PRODUCT CATEGORY

CONTACT US

+86 18553788237

+86 18553788237

MESSAGE

RECOMMEND

![New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine]() New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore

New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore![Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine]() Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore

Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore![DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function) DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)]() DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

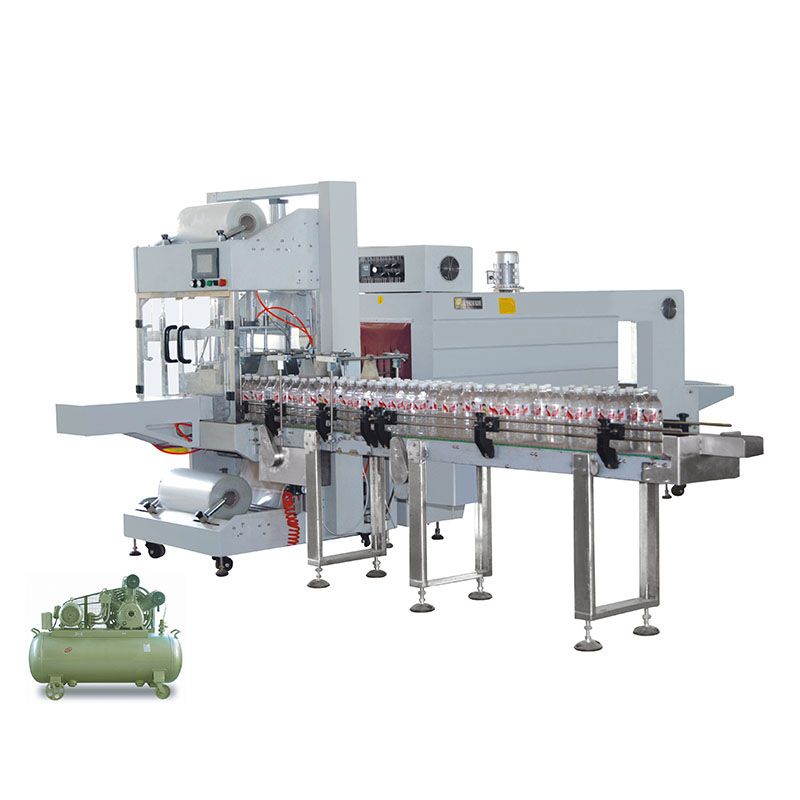

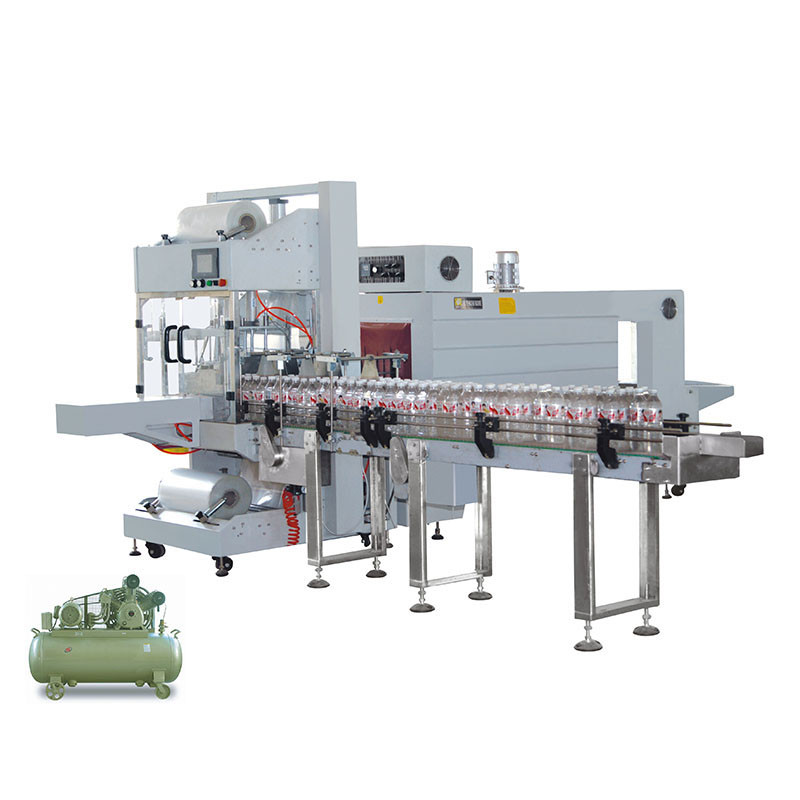

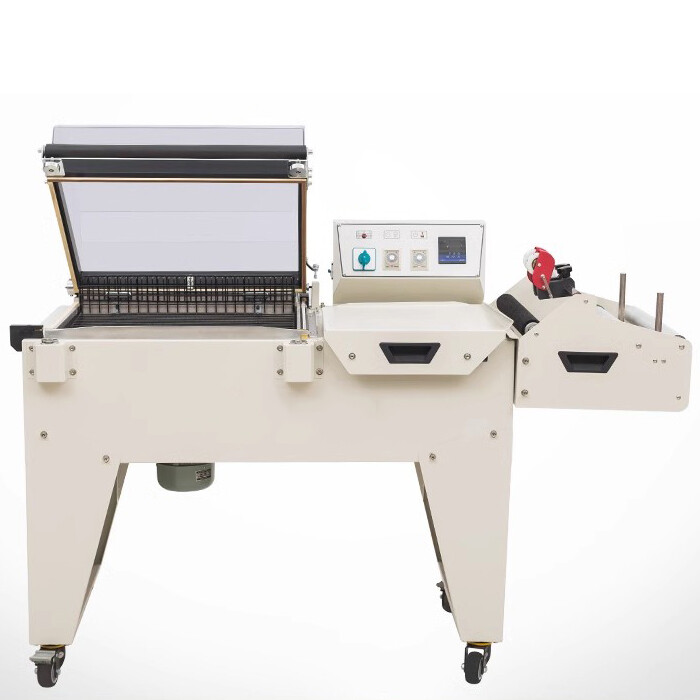

QSJ-5040A & BSE-5040A Automatic Water Bottle Sleeve Wrapper Plastic Film Sealer and Cutter and Shrink Tunnel Packaging Machine

Inquiry Now →

Product Description

QSJ-5040A & BSE-5040A Automatic Water Bottle Sleeve Wrapper Plastic Film Sealer and Cutter and Shrink Tunnel Packaging Machine

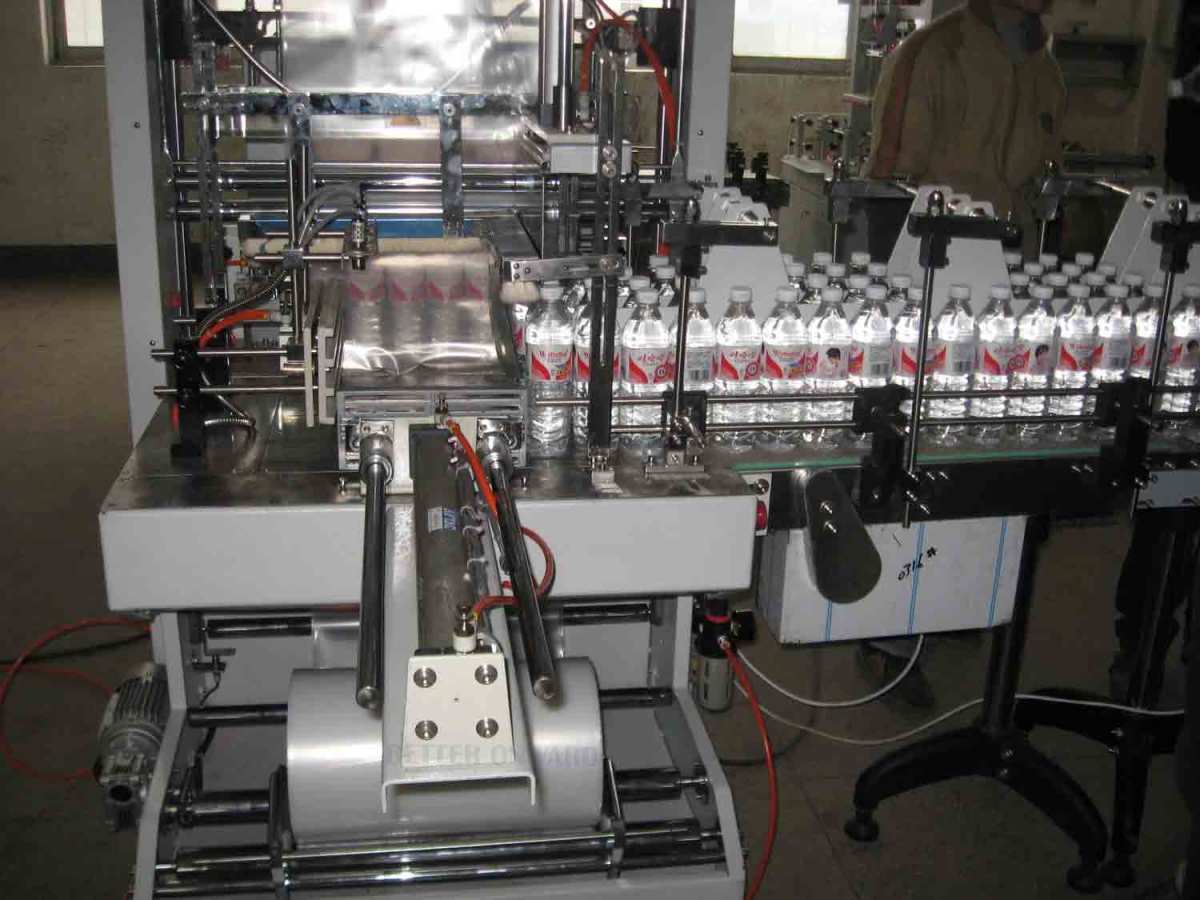

QSJ-5040A automatic sleeve wrapper is suitable for wrapping products such as pop-cans, water bottles, wine bottles, plastic bottles, glass bottles, etc.

It could work with BSE-5040A or other models shrink packaging machine.

After being packed by these two machines, the goods is beautiful, tidy, dust proof, moisture proof, anti-damage. The packaged goods are easy to handle and storage.

Specification

QSJ-5040A Bottle Sleeve Wrapping Machine

According to the plastic film's thickness, could adjust the sealing temperature.

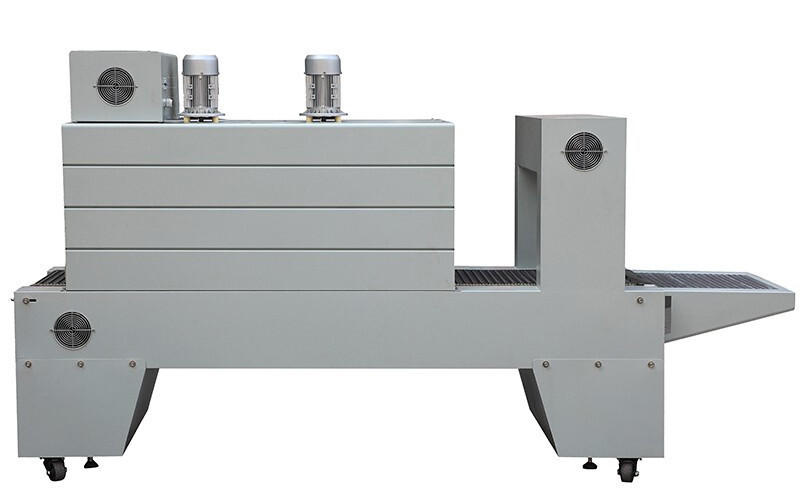

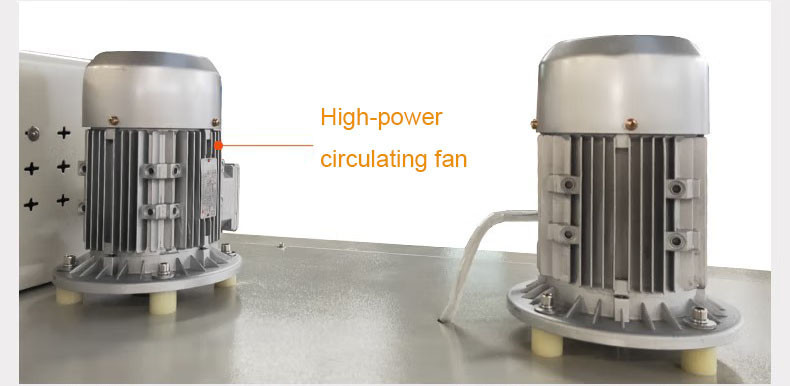

BSE-5040A Shrink Packaging Machine

The product is wrapped by shrink film, after heating, the plastic film will shrink and wrap the goods tightly.

It will fully displaying the appearance of the goods. After packaging, the goods is sealed and protected from moisture and

contamination.

When the temperature of the shrink tunnel reaches the setting temperature, the machine will stop heating automatically.

When the temperature of the shrink tunnel is lower than the setting temperature, the machine will heat

automatically, is energy-saving and environmentally friendly, saving electricity.

Applicable plastic film material: PE, POF, PVC, PP.

Net & chain type conveyor ensure heavy duty load working, and hot air circulation ensure excellent shrink effect.

Packing Effect

Message

Related Products