PRODUCT CATEGORY

CONTACT US

+86 18553788237

+86 18553788237

MESSAGE

RECOMMEND

![New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine]() New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore

New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore![Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine]() Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore

Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore![DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function) DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)]() DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

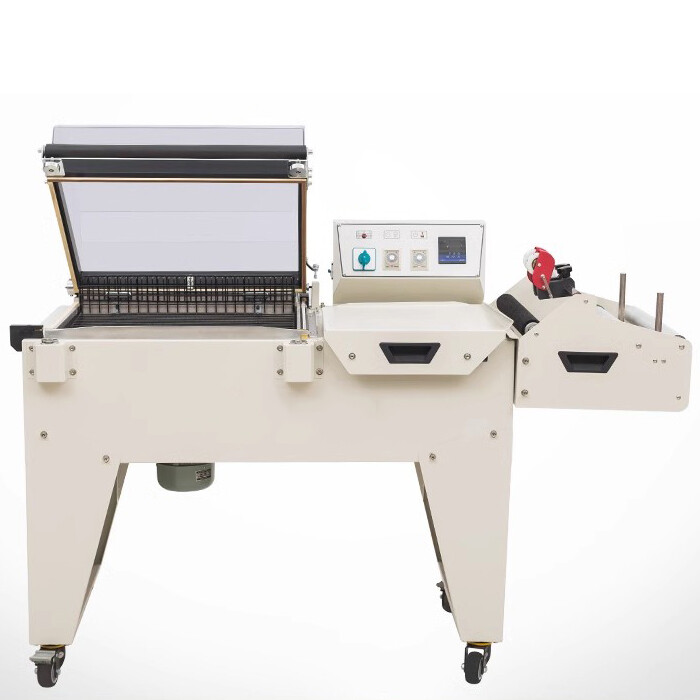

DFM5540 Semi-automatic 2 in 1 Plastic Film L bar Sealing and Cutting and Heat Shrink Wrapping Machine

Inquiry Now →

Product Description

DFM5540 Semi-automatic 2 in 1 Plastic Film L bar Sealing and Cutting and Heat Shrink Wrapping Machine

Our DFM5540 machine wrap the outside of the goods with plastic film. By heating, the plastic film will be shrunk, to wrap the goods tightly, to fully display the appearance, improve the value and sales of the goods. Meanwhile, the packaged goods is moisture-proof and anti-dirty.

Our DFM5540 machine pack the products with a layer of plastic film, which makes the packaging more beautiful and firm.

Main Features

1.Combined sealing, cutting and shrinking in one operation.

2.One set economical packaging machine for small-scale production.

3.Applicable plastic film material: POF, PVC.

4.Two functions for option: 1. Seal-Cut function. 2. Seal-Cut-Shrink function.

It is widely used in the external packaging of beverage, gift box, electronic devices, hardware, cosmetics, toys and plastics, etc.

1.Combined sealing, cutting and shrinking in one operation.

2.One set economical packaging machine for small-scale production.

3.Applicable plastic film material: POF, PVC.

4.Two functions for option: 1. Seal-Cut function. 2. Seal-Cut-Shrink function.

It is widely used in the external packaging of beverage, gift box, electronic devices, hardware, cosmetics, toys and plastics, etc.

Specification

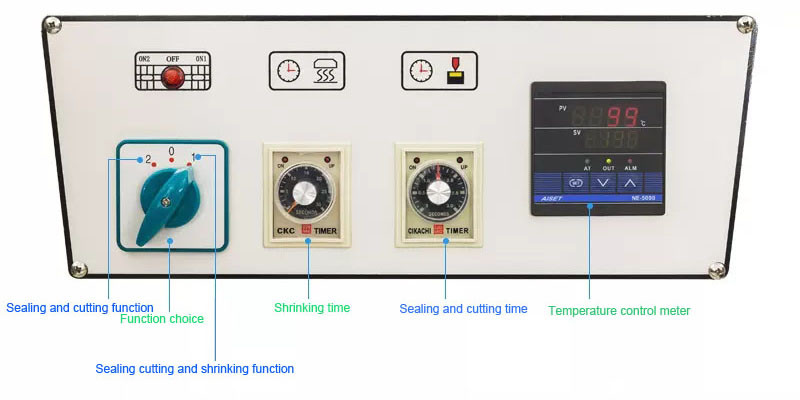

Operation Panel

We could adjust the sealing and cutting time and shrinking time, and control the temperature.

Match with the large fan blade device, forms a good air circulation system in the shrink tunnel, making the shrinking effect more even.

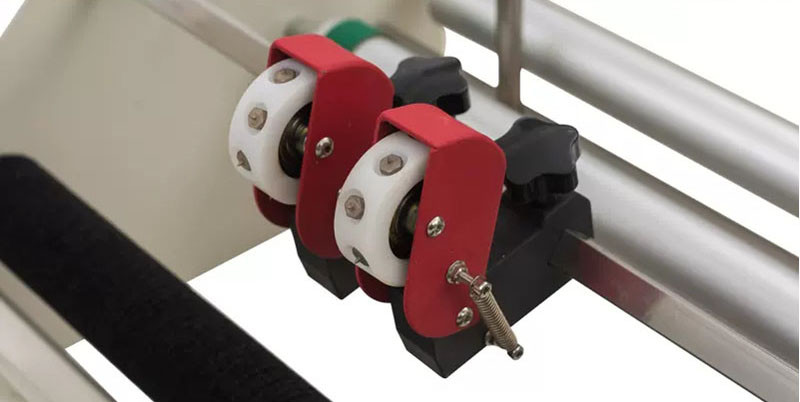

The load of film frame roller is heavy.

The perforating position is adjustable. According to the size of the film, could adjust the interval.

It is equipped with the large motor, is powerful. The service life is long.

Alloy sealing blade, anti-adhesive, the sealing is neat.

The film separation plate to separate two layers of plastic film.

Message

Related Products