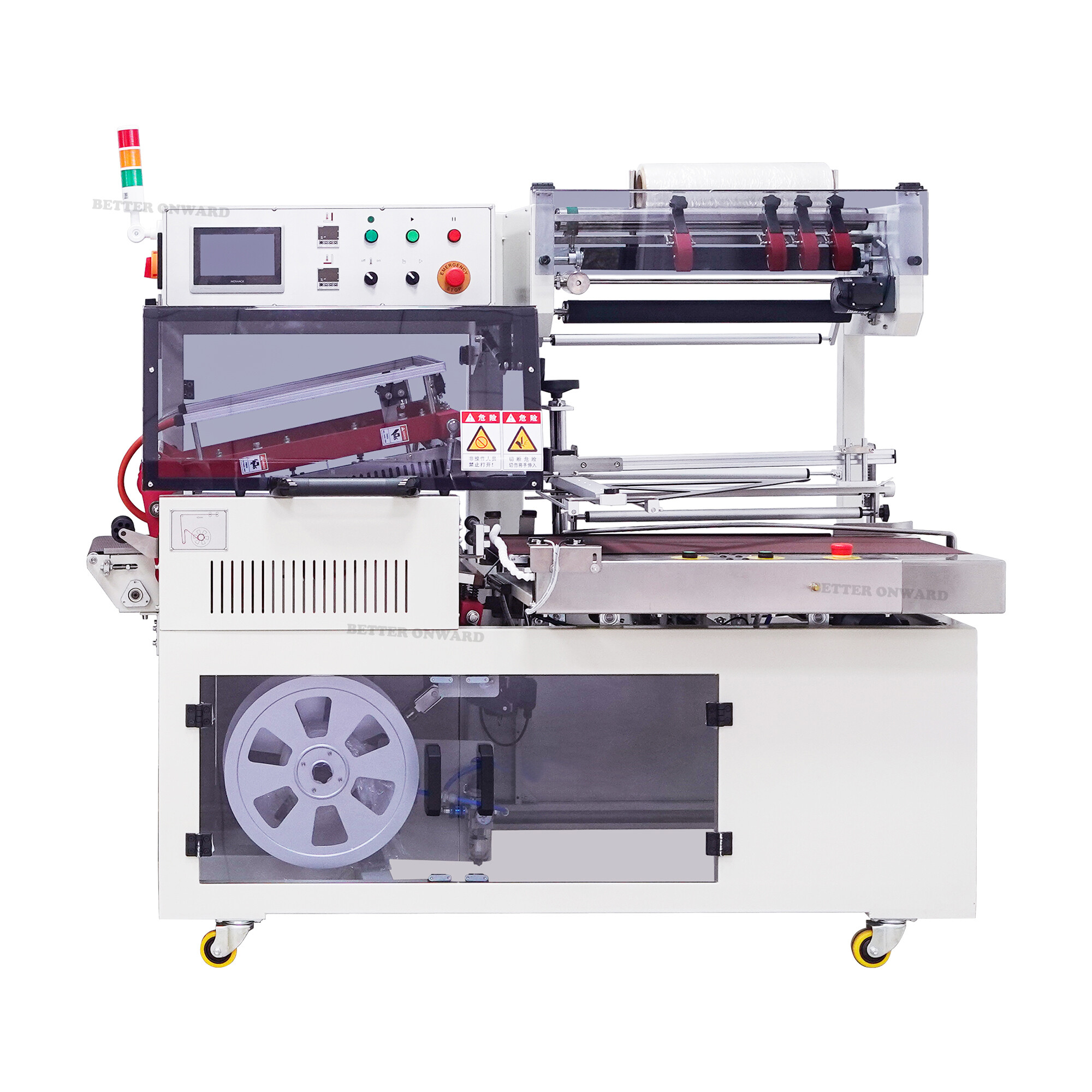

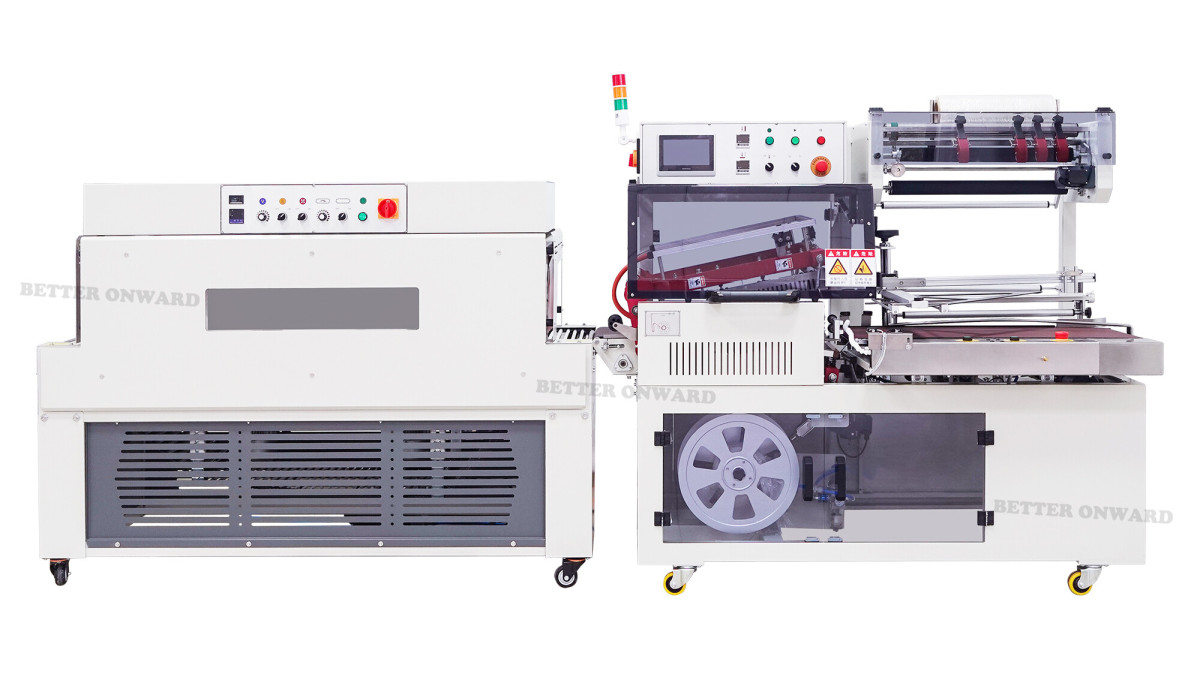

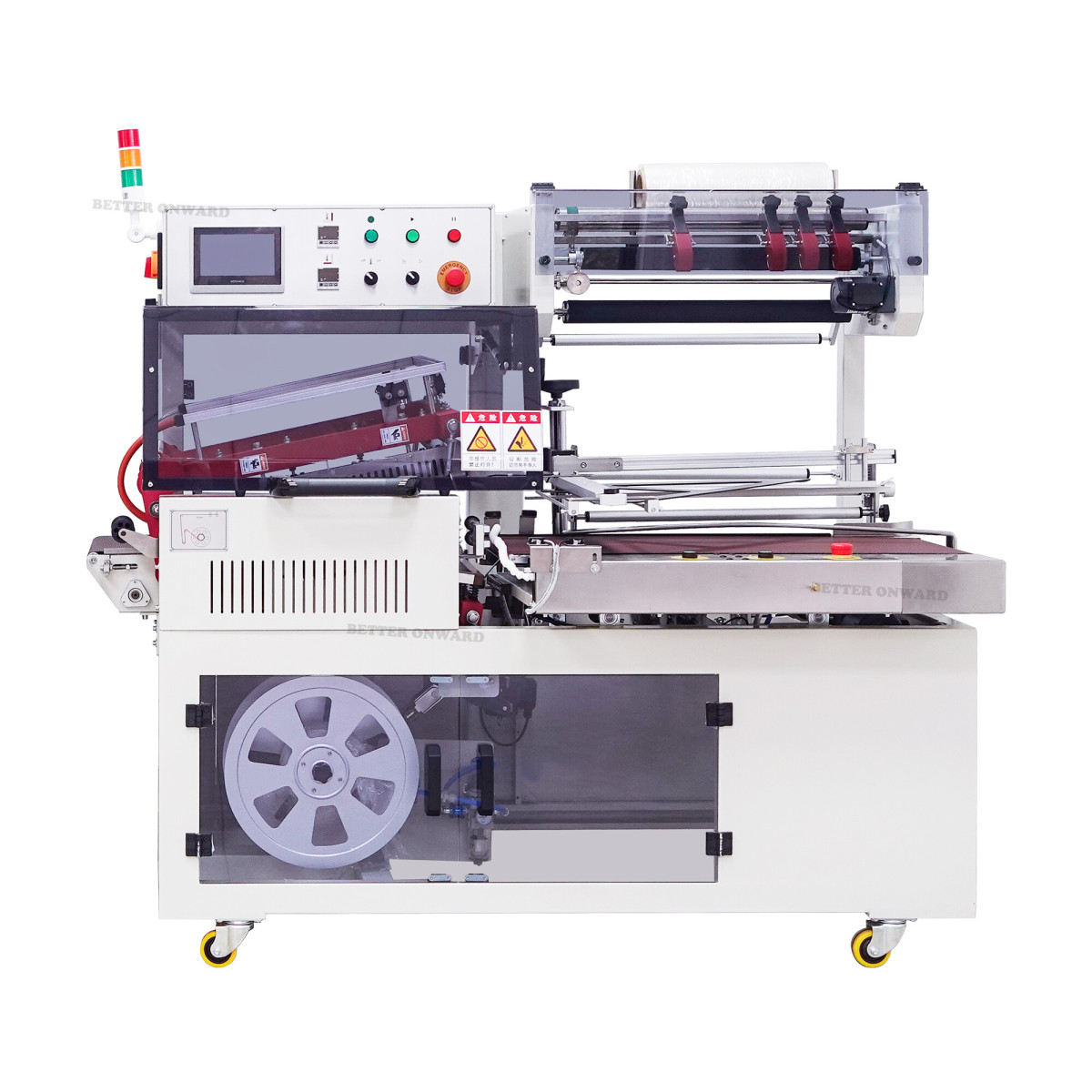

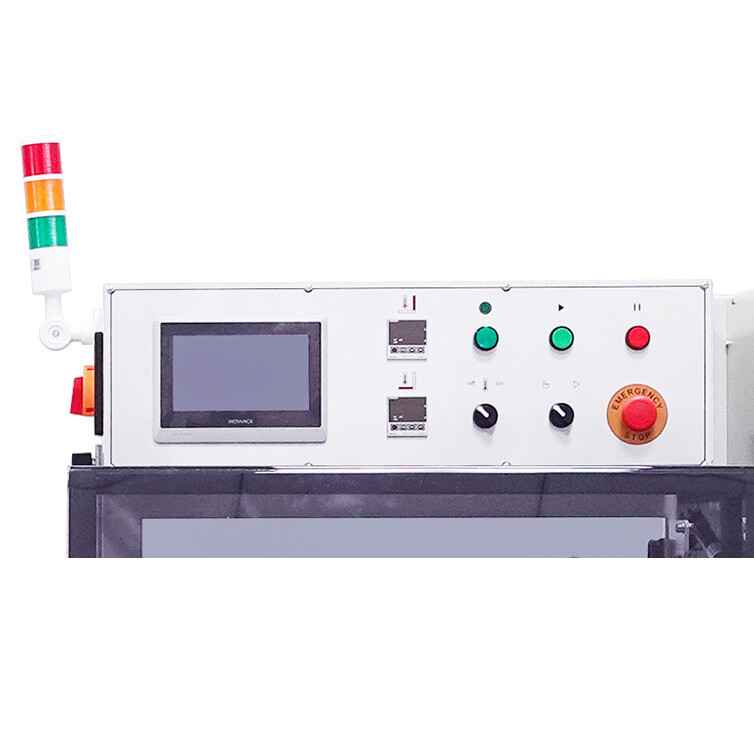

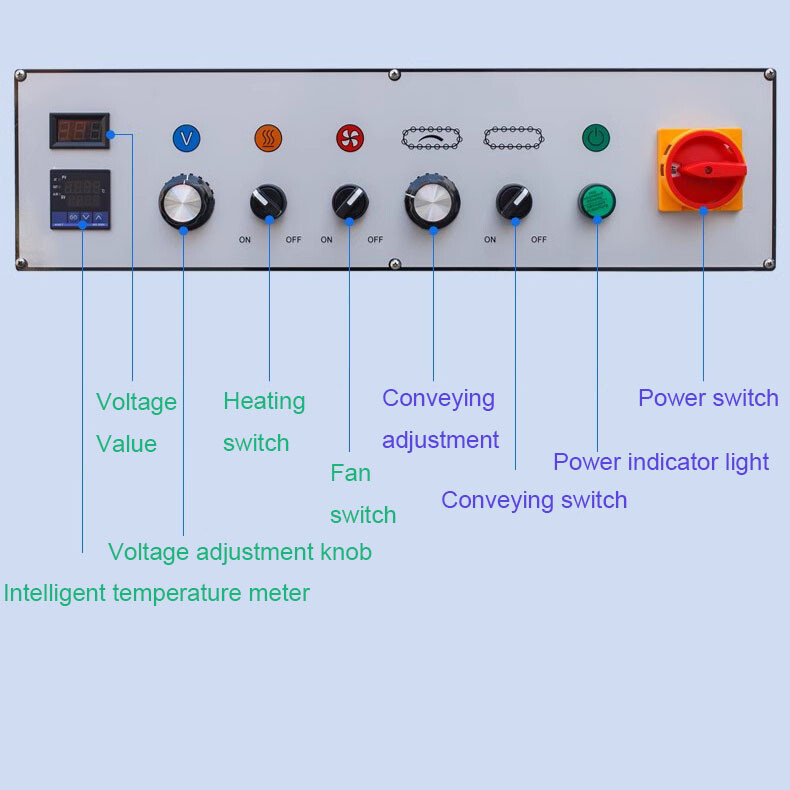

PLC control, high reliability, strong resistance to interference, powerful and flexible.

Photoelectric sensor has high sensitivity and precise response.

Audible and visual alarm system, automatic alarm,provide safety protection in case of improper operation.