Worktable height: 450mm

PRODUCTS

PRODUCT CATEGORY

CONTACT US

+86 18553788237

+86 18553788237

MESSAGE

RECOMMEND

![New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing Machine]() New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore

New Design DFD50I Electric Vertical Intelligent Packaging Machine Express Bags Labeling and Sealing MachineMore![Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing Machine]() Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore

Hot Sale DFD50 Electric Vertical Intelligent Express Plastic PE Bags Packaging Machine High Speed Bagging and Sealing MachineMore![DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function) DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)]() DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

DFD50A Electric Vertical Intelligent Express Bags Sealing and Packaging Machine (with Instant Printing and Labeling Function)More

Product Description

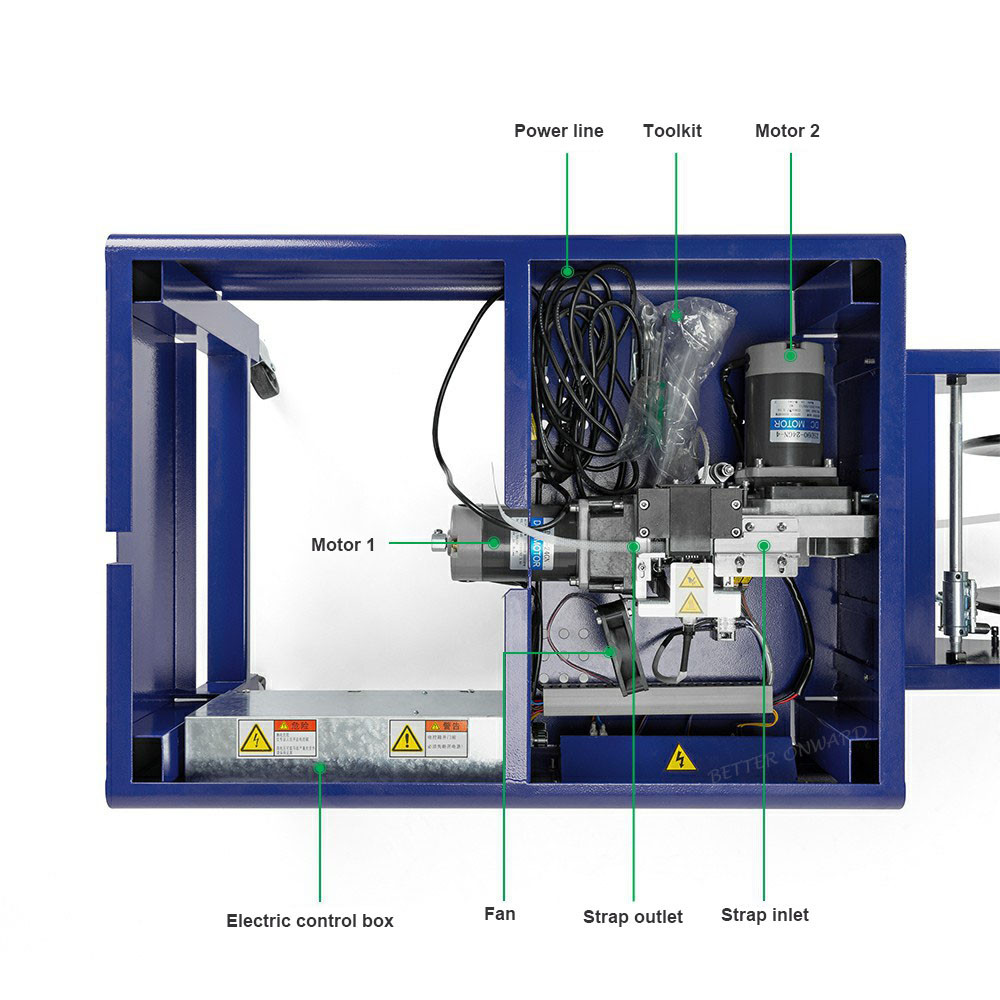

YS-A2L Low-table 110V 220V Semi-automatic 5-15mm PP Packing Band Strapping Machine

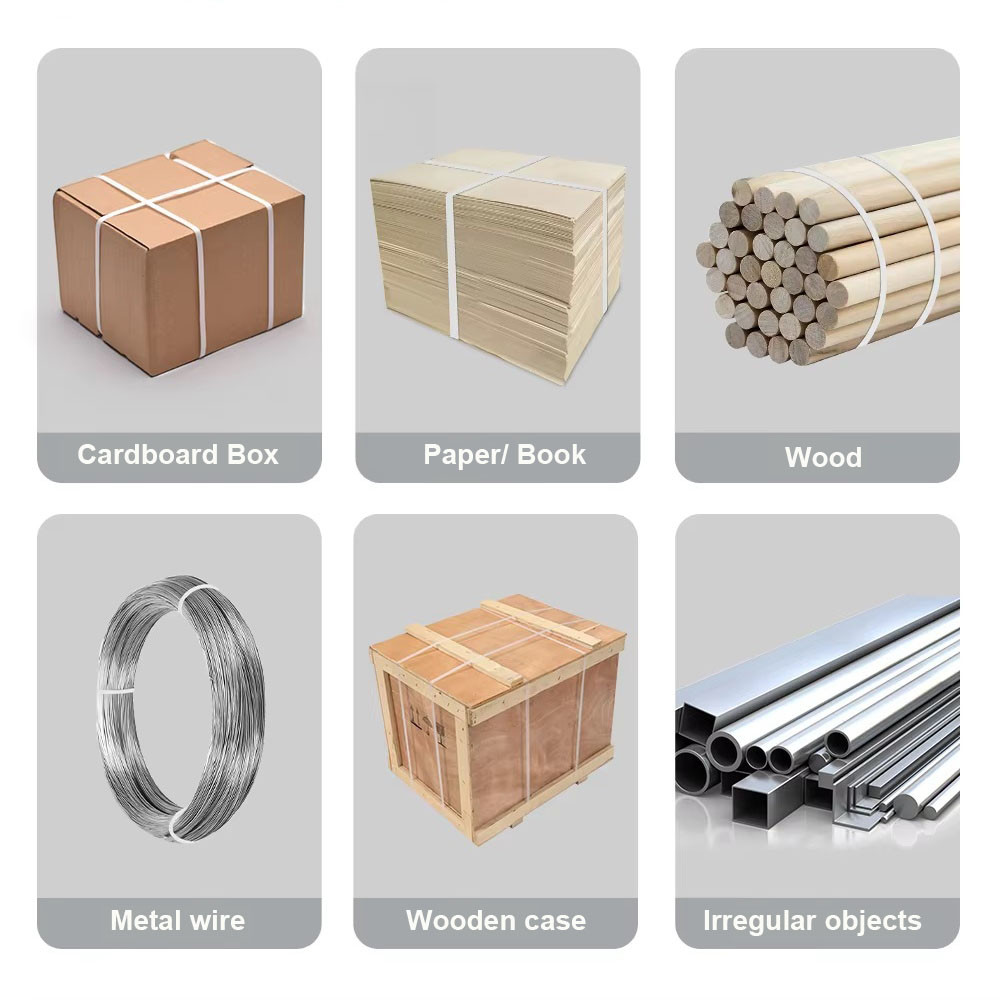

Our YS-A2L semi-automatic strapping machine is an automatic packaging machine, is used to apply PP Straps on Carton Boxes, Newspaper Piles, Oil Tin Cans, Flexible Bags, Books, Brochures, Bricks, Stones, Metal Pipes, etc. In order to unitize or bundle together for easy carrying, transporting or storing.

Working speed: Strapping cycle in 3 seconds.

Fast speed, high working efficiency, save time and effort.

Specification

2) To tension the object.

3) Two layers of strap is heated.

4) Cutting off the strap.

Adhesion mode:Hot melt

Control Panel

1) Power switch (ON/ OFF)

2) Timer (length adjustment for strap feeding)

3) Strap tension button

4) Feed/ Home (Manual feeding/ Reset button)

2) Timer (length adjustment for strap feeding)

3) Strap tension button

4) Feed/ Home (Manual feeding/ Reset button)

Our YS-A2L Strapping Machine gained CE certification.

Voltage: 110V/220V

Power:250W

Strap width: 5-15mm (+/-1mm)

Thickness: 0.5-0.8mm (+/-0.1mm)

Strap coil width: 160-190mm

Application:

Message

Related Products